SE-TEC

the company for

electronics

# Custom specific solutions

# Custom solutions

We support you

from the Start

We support you from the start.

We have a network of hardware and software developers, layout designers and EMC specialists with whom we work closely.

On the basis of your catalogue of requirements, we can develop and project tailor-made solutions that can be implemented quickly and cost-effectively in production. Whether new development or redesign – our partners stand for innovation and product reliability.

Another decisive factor for your product success is the selection of the suitable manufacturing technology and the associated adjustment of the layout for a reliable and cost-optimized manufacturing process. Benefit from our decades of know-how and let us advise you on the subject of “Design for Manufacturing”.

# SE-TEC LAYOUT // SUPPORT

# Project management

# Project managment

One contact

for all topics

Five experienced project managers and two assistants support and advise you competently and professionally.

Support of your project from the beginning by one direct contact person

- Review of your project documents

- Clarification of technical and commercial questions

- Open quotation calculation with details of our procurement information

- Support of the project during the entire manufacturing process

- Sustainable project support

- Use of innovative software tools

# Material management

# Material managment

The price stands or falls

with the procurement

Automated, precise and reliable counting of components by means of an X-ray component counter. The innovative techniques of image processing and height measurement in the µm range ensure the detection and analysis of all visible defects on components and solder joints. In this way, we ensure a minimum defect rate. In our test bay, we have a wide range of options for programming, calibrating, commissioning and function testing your assemblies. Endurance tests and burn-in tests are also possible.

- our high flexibility and short delivery times thanks to extensive stockpiling of standard components and close relationships with our suppliers

- Avoidance of delivery delays and production delays through constant monitoring of the dispatching

- the provision of all material for delivery schedules from framework agreements

- the minimization of the capital tied up in your warehouse

- ESD and MSL-compliant storage and handling of electronic components

- Precise order picking

- Permanent inventory

- Automated, precise and reliable counting of components by means of an X-ray component counter

So, you can concentrate on your core competencies.

#Production

# Production

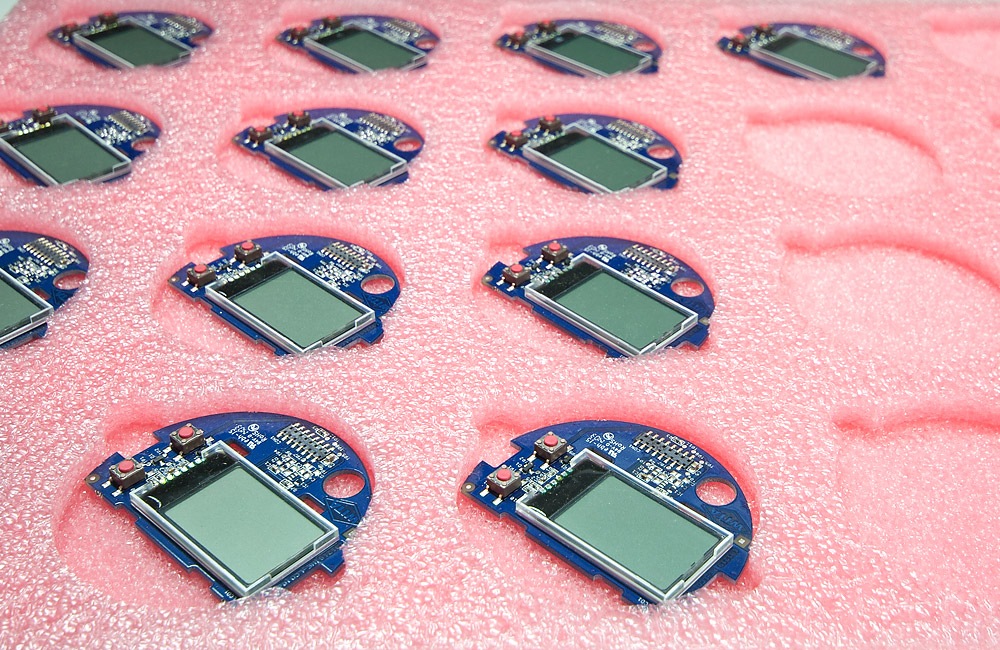

From samples

to series

We deliver sample assemblies in series quality within a very short production time.

So that your assembly can be manufactured perfectly and cost-effectively in series production, we will make you suggestions for functional or manufacturing improvements with the help of an initial sample test report.

# Testing and programming

# Testing and programmig

100 % tested

assemblies

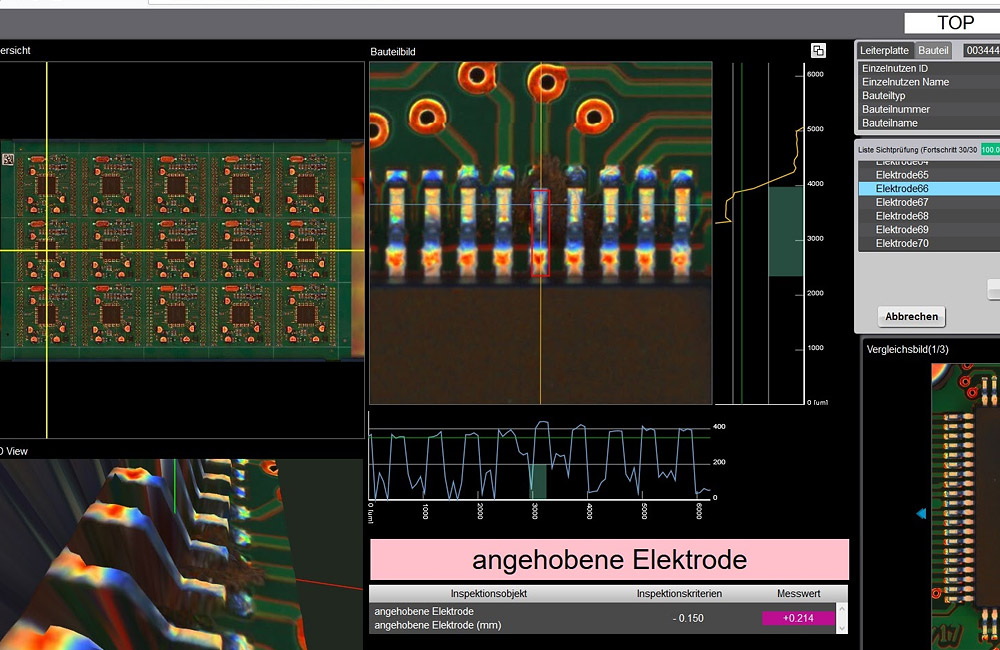

In our quality assurance, we use modern optical systems from the manufacturers Omron and Göpel to inspect your assemblies.

The innovative techniques of image processing and height measurement in the µm range ensure the detection and analysis of all visible defects on components and solder joints. In this way, we ensure a minimum defect rate.

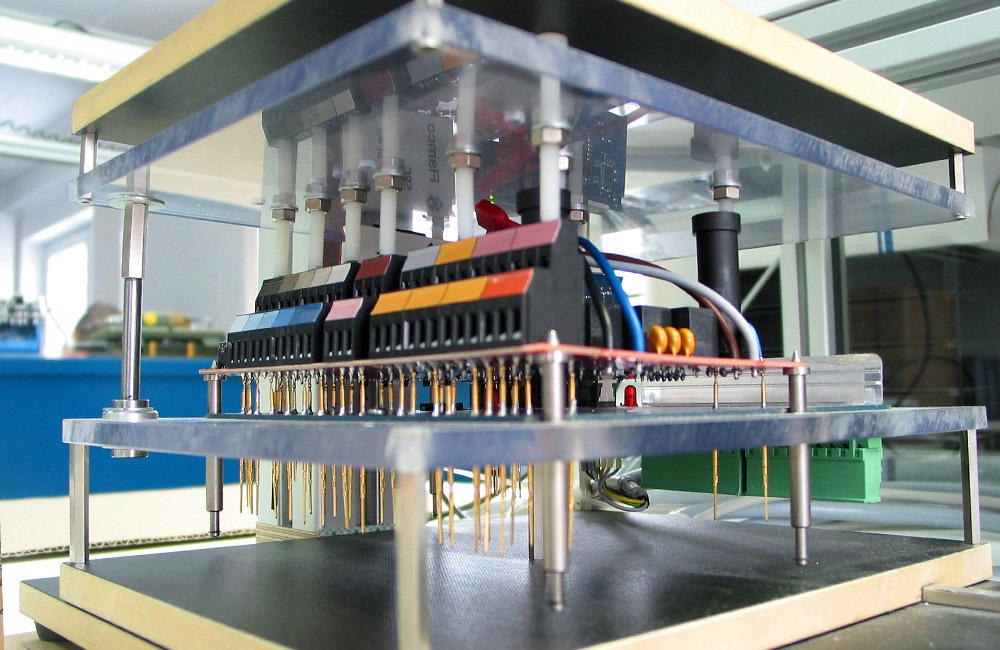

In our test bay, we have a wide range of options for programming, calibrating, commissioning and function testing your assemblies. Endurance tests and burn-in tests are also possible.

# Complete device assembly

# Complete device assembly

Flexible

manual assembly

- Production of complete functional units

- Programming and commissioning of the modules

- Sealing and potting

# Logistics

# Logistics

We get your products

on their way

- Execution of incoming and outgoing goods by trained specialists

- Storage of the components in our vertical storage system

- Vacuum packaging and storage of moisture-sensitive components

- Use of anti-static packaging materials

- Use of resource-saving return packaging

- Delivery on the requested date

- Reliable and economical delivery in cooperation with efficient transport companies