SE-TEC

the company for

electronics

# archive 2019 //

Tuesday November 12, 2019 // 9.48 a.m.

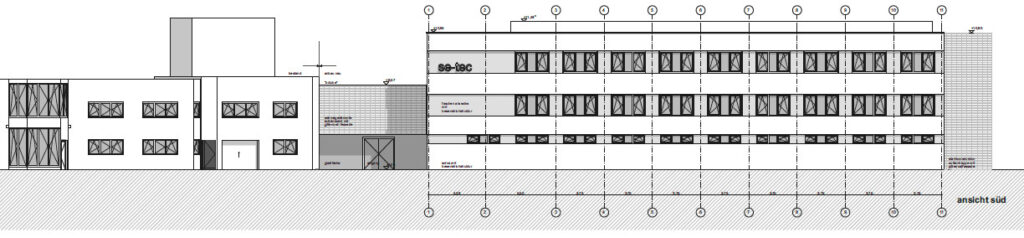

Locationexpansion

With the expansion of our production and storage area, we want to create the basis for mastering the challenges of a new decade and further expanding our performance for you.

A three-story building is being built east of the existing production facility. The existing building and the extension are connected to each other by means of a bridge over both the ground floor and the first floor.

The individual floors should fulfil the following functions:

- Ground Floor Expansion and optimization of SMT production

- 1st floor: Expansion of the company’s internal office and storage space

- 2nd floor: office and production space for innovative development companies

The completion of the new building is planned for Q3 / 2020. We would be happy to invite you to get a personal impression.

Your Olaf Segler // Managing Director SE-TEC GmbH

# archive 2018 //

Friday 1st June 2018 // 11.25 a.m.

SE-TEC Project Management Assistant

# SE-TEC PROJECT MANAGEMENT ASSISTANT SANDRA LUDEWIG

To support the project management, we welcome Ms. Sandra Ludewig as the first project management assistant in our company.

Her operational tasks include communicating with customers and suppliers, processing parts lists, obtaining and evaluating offers, monitoring deadlines and preparing offers. In this area, she supports the project managers individually and as required.

Other essential tasks are material planning, ordering and monitoring.

To strengthen our team, we are currently looking for a further project management assistant. If we have piqued your interest, please contact us. For more information, see Jobs

Your Christian Giese / SE-TEC GmbH

# archive 2017 //

Tuesday April 18, 2017 // 2:05 p.m.

DIN EN ISO 9001: 2015 certifikation

ISO 9001: 2015 builds on the 2008 standard. The following fields of action should be considered by those responsible in the organization.

- Strategic direction of the organization

- Expansion of the target groups

- Process management

- Allocation of responsibilities

- Risk management

- Knowledge management

- Documentation

After the first certification in 2014, on April 19, 2017, after a successful audit by DEKRA, the company was re-certified according to DIN EN ISO 9001: 2015.

Over the years we have succeeded in further developing our QM system and thus making work processes and procedures even more efficient. Our customers, suppliers and employees continue to make a significant contribution to a functioning system. In order to keep pace with technical progress, we regularly invest in new machines and systems. With the help of prevention plans, risks and opportunities are identified, analysed and assessed in advance. The aim is to take advantage of the opportunities and eliminate risks. Constant contact with our customers helps to identify and develop strengths and to catch up with weaknesses. The inclusion of all employees in the expansion of the system ensures a high level of acceptance in the entire team.

In order to continue to meet your requirements in the future, we strive to further expand our QM system.

The best quality for your products – you can count on us.

# archive 2016 //

Friday 12th September 2016 // 8:47 a.m.

We are exhibiting for you at the EMV seminar in Magdeburg

14th EMV seminar – industrial seminar

Oktober 25, 2016

Experimental factory Magdeburg

Also, this year we are exhibiting for you at the EMV industry seminar in Magdeburg. The now 14th EMV seminar has the motto:

What does the future hold for the practical implementation of EMV in various development areas?

SE-TEC GmbH would like to take the opportunity and introduce itself to you. We would like to get to know interested companies and potential new customers in personal discussions and convince them of our skills and know-how. Of course, this also applies to our long-standing customers who already appreciate our quality and our competence.

The 14th EMV industry seminar will take place on Tuesday, October 25th, 2016 in the experimental factory in Magdeburg on the university premises.

Friday August 8th 2016 // 9:37 a.m.

SMTproduction line

Since the beginning of 2016 we have been able to produce medium and large quantities even faster and more efficiently. Our new SMT production line from the company Juki offers high placement speeds of up to 50,000 units / h (IPC 9850). In order to continue to meet our high standard of production quality, the machines have numerous camera systems and barcode readers that allow us to continuously monitor and control facilitate manufacturing.

In addition to the RX-6 pick-and-place machine, the fully automated stencil printer – GL from the same company, fits perfectly into the line. The printer is fully equipped with automatic stencil cleaning, 2D SPI, a patented circuit board clamping system, memory function of the stencil position and numerous other functions.

In addition, our flexibility is retained in the small and medium-sized range with the placement machines from the manufacturers Mycronic and Essemtec. With this mix of manufacturing technology, we offer you a quick and high-quality solution for all your inquiries and projects.

Thursday, September 4th, 2016 // 8:02 am

2K-Mixing- and dosing system 2016

With the purchase of two 2K mixing and dosing systems specially tailored to the requirements of our standard potting compounds, we can offer you the potting of your assemblies in excellent quality. We use the following potting compounds from Lackwerke Peters as standard.

Friday Juli 03, 2016 // 10.22 a.m.

Company relay 2016

In bright sunshine and 34 degrees, the mayor of Magdeburg, Dr. Lutz Trümper gave the starting signal for the 8th company relay.

A total of 11,000 visitors, including 5,000 active runners from around 500 companies, made their way to the Elbauenpark Magdeburg on this day.

We were also there this year and sent two teams

(SE-TEC BLITZE) into the race.

# archive 2015 //

Monday October 26, 2015 // 04.09 pm

THT wave soldering system

As part of the 2015/2016 investment package, the THT production was upgraded as a first step. The System 8100 PCS wave soldering system is designed for lead-free applications in medium to large production series.

Thanks to the modern soldering nozzle geometry from SEHO, complex SMT / THT assemblies can also be soldered in addition to conventional THT applications.

In order to be able to produce faster, more precisely and with higher quality in the future, the system has the highest flexibility and can be easily and quickly converted if necessary. The automated conveyor belt enables a high throughput.

# archive 2014 //

Wednesday October 1st, 2014 // 8:47 a.m.

Partner company for a dual study

In cooperation with the Magdeburg – Stendal University of Applied Sciences, we welcome our first dual student to the company. The dual course of study combines theory and practice. The standard period of study is 7 semesters, in which the student spends time both at the university and in the company. The period is approximately 3 months in each case.

The semesters are divided into different subject areas, such as economics and business, finance, marketing, human resources, etc. The student then tries to apply the knowledge he has learned in the practical phase. At the end of the semester, the exams at the university and practical work during the time in the company usually follow.

Another important point is the monthly remuneration of the student by the company. No additional financial resources are required to make ends meet during your studies.

“I can only warmly recommend this type of dual study to everyone.”

If you have any questions about the company or the dual study program, I am at your disposal. more

- Christian Giese // dual business administration student

- Tel.: +49 (0) 391 / 60 77 26 – 27

- Mail: giese@se-tec.com

Friday July 11th 2014 // 6:50 p.m.

We are exhibiting for you at the

FMB in Bad Salzuflen

The innovation fair for suppliers to the mechanical engineering industry is to ‘bring designers and planners together in a target-oriented manner and build communication bridges for existing and new networks.’ SE-TEC GmbH would also like to introduce itself here and would like to get to know you in a personal conversation. This of course applies to our long-term customers who already appreciate our quality and personality, but also to interested companies and potential new customers whom we would like to convince of our skills and know-how.

You will find us at booth C44 in hall 20 of the Bad Salzuflen exhibition centre.

We look forward to your visit!

Friday June 27th 2014 // 3:45 p.m.

DIN EN ISO 9001:2008 certificate

On April 24, 2014, we were able to complete our certification according to ISO 9001 – 2008 with DEKRA.

The principles of the QM system according to 9001 have been our daily practice for some time. In recent years, we have gradually analysed all production processes as well as the upstream and downstream processes and adapted them to the requirements of ISO 9001: 2008. The inclusion of all employees in the design of the new QM system ensures high acceptance in the entire team.

With all our strength we will keep the new QM system alive. Constant and critical attention, openness to new technological requirements, close cooperation with our partners and a distinctive team spirit are the supporting pillars for the continuous development of SE-TEC GmbH.

With the ISO 9001: 2008 certification you will also be in good hands with SE-TEC in the future.

The best quality for your products – you can count on us.