SE-TEC

the company for

electronics

Friday 4. March 2022 // 11:37 a.m.

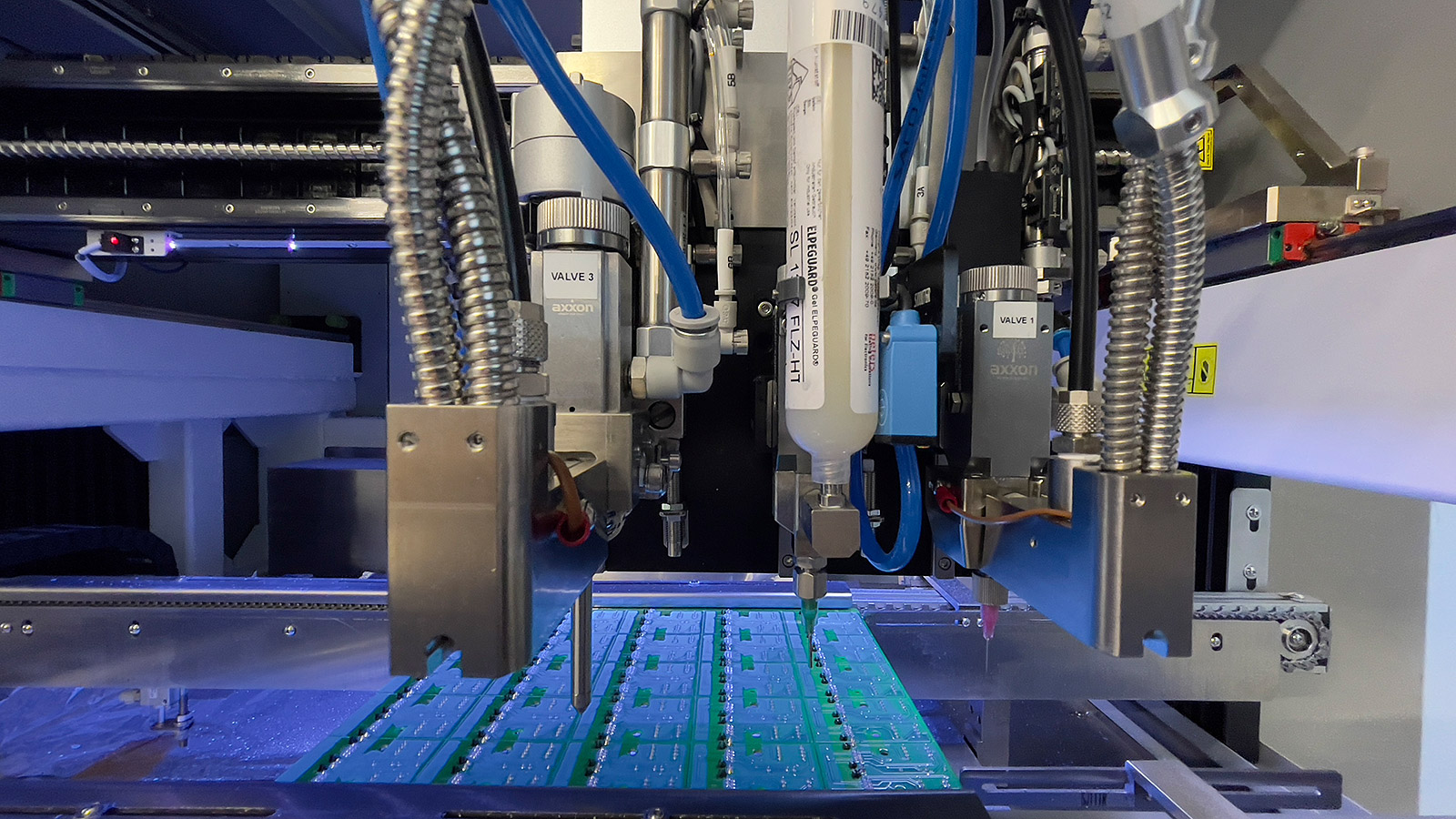

Automated conformal coating process

We can offer you a valuable addition to our range of services with the purchase of the new painting system, a MYC50 from Mycronic. Numerous features such as laser height measurement, heating modules and closed loop enable precise dosing and even distribution of the paint material, so that an optimal protective layer is achieved on the circuit boards.

Because it is equipped with three different valves, a wide range of requirements can be covered. A spray valve is used to coat large areas. Even hard-to-reach places can be reached using a needle valve. The dispenser is used to apply dam material so that sensitive components such as connectors are kept free of paint.

# painting system MYC50 from Mycronic // 02/2022

The reliability and service life of your assemblies can be increased or extended by using the proven protective coating SL 1307 FLZ/2 from Lackwerke Peters. You get excellent corrosion protection over a wide temperature range from -65 to min. +125°C. If you would like to learn more about conformal coating, the painting of electronic assemblies and the benefits for the reliability of your products, please contact us.

We would be happy to speak to you personally.

Your Sebastian Schollmeyer / Operations Manager

Thursday 17. February 2022 // 16:35 Uhr

SE-TEC GmbH invests in depanelling processes for maximum precision and assembly reliabilityt

We are pleased to inform you that SE-TEC GmbH has further expanded its production facilities and now has a system for CNC milling depaneling and laser depaneling.

The combination of individual circuit boards in multiple production panels is an essential step in reducing the handling effort per circuit board and is therefore essential for almost every product.

When it came to the required panel separation, we made a conscious decision not to use conventional dividing separation processes, as these can pose potential risks for sensitive components such as ceramic capacitors. Microcracks in components and solder joints can jeopardize the reliability of the entire assembly. For this reason, we rely on cutting or laser cutting processes from prototype production to series production of sensitive assemblies. The CNC milling depaneling machine offers exact separations with tight tolerances and minimal influences on the components. In addition, the chip is specifically sucked off through channels in order to maintain the necessary cleanliness of the assembly.

# CNC milling depaneling and laser depaneling – 02/2022

We use the system to adapt particularly demanding assemblies ourselves at attractive conditions and in short throughput times. Laser depaneling is characterized by its non-contact and non-contact method, which enables a particularly gentle separation of the panels. With this investment in innovative separation processes, we are underscoring our commitment to quality and reliability. Our customers can rest assured that their assemblies will be treated with the utmost care and will perform at their best.

Please contact us for more information about our new separation processes and their benefits for your specific requirements. Visit us and see our advanced manufacturing technology in action

Your Sebastian Schollmeyer / Operations Manager